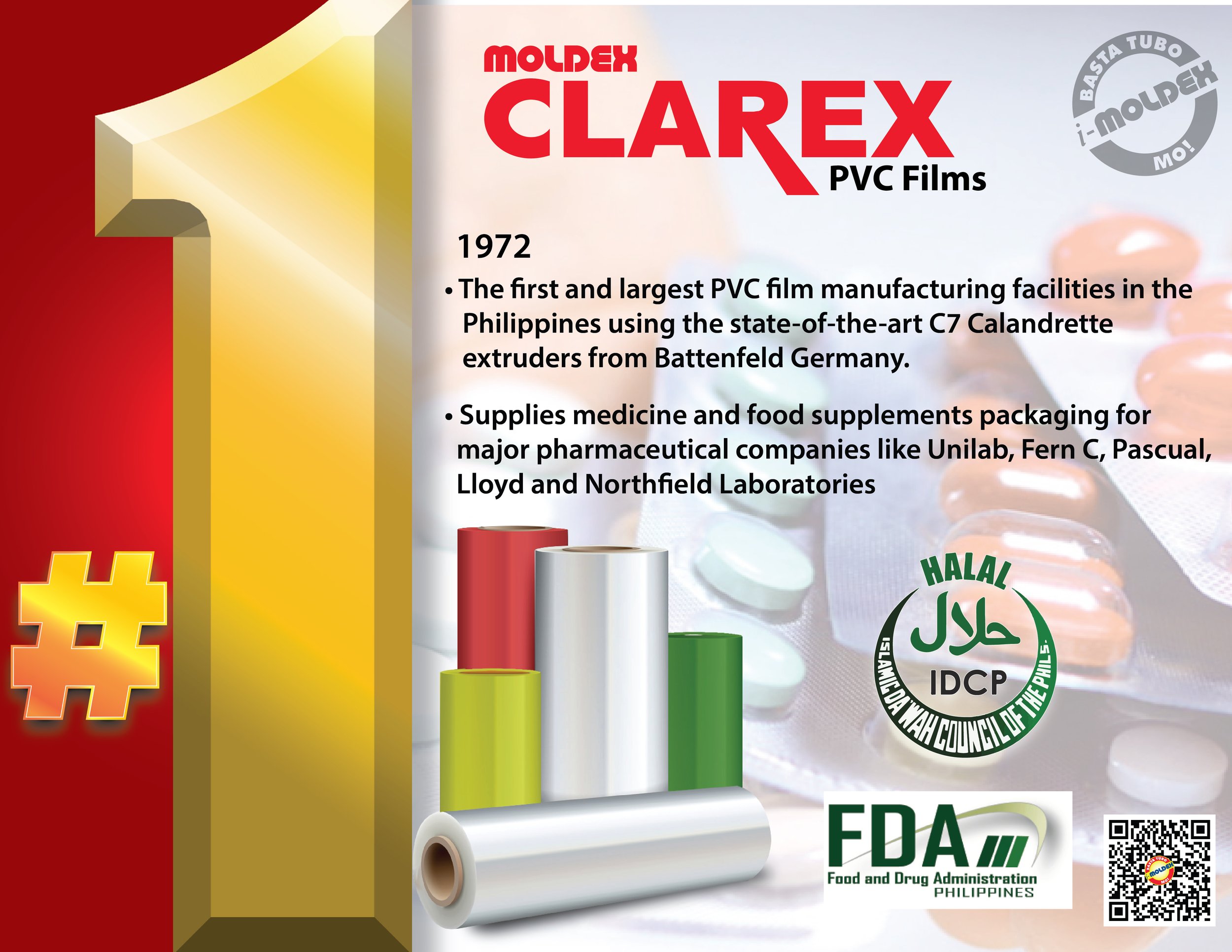

MOLDEX was the first and largest PVC film manufacturing facility in the Philippines

Using the state-of-the-art C7 Calandrette extruders from Battenfeld Germany. Clarex PVC Films supplies medicine and food supplements packaging for pharmaceutical companies like Unilab, Fern C, Pascual, Lloyds and Northfield Laboratories.

MOLDEX was the first to introduce large-diameter HDPE pipes in the Philippines

It has high abrasion resistance to resist damage from gushing rocks, ores and debris. Moldex HDPE flexibility does away with pipe bend fabrication costs. And it has a light-weight (vs. metal pipes) make it easier for HDPE pipes to be pulled up and down the mining tunnels.

MOLDEX introduced the first corrugated flexible PVC-U electrical conduit in the Philippines

With "self-extinguishing" property. MOLDFLEX has become a household name so popular that all other brands have also been called "MOLDFLEX" by the market. But beware of fake MOLDFLEX products to avoid fire. Look for genuine "MOLDFLEX ELECTRICAL" marking.

MOLDEX introduced the first and only 232 psi potable water PVC pipe in the Philippines

This is perfect for buildings using pressure pumps like high-rise condominiums. MOLDEX Blue is now the No. 1 selling Blue PVC-U pipes and fittings in the Philippines. It is also certified safe and non-toxic by PIPAC.

MOLDEX was the first to introduce PVC-U DWV with dual jointing system in the Philippines with Sanimold Extra

It is also the first to conform to ISO 3633 metric sizing and dimension for PVC-U DWV pipes.

Not resting on its laurels, MOLDEX further improves Sanimold Extra in 1995 by being the first to innovate DWV piping system with efficiency and convenience features:

- Patented built-in slope (2.5°) in bends and tees

- Patented air and water-tight seals in clean-out

MOLDEX introduced ECOSAFE PPR, the first PPR pipe produced in the Philippines

This product is the embodiment of our Filipino-first principle as the market becomes flooded with cheap, substandard white PPR pipes from China. MOLDEX Ecosafe PPR conforms to ISO 15874 strict quality standards and is certified safe and non-toxic by PIPAC. Filipinos can now enjoy safe hot and cold water pipes made in our country.

MOLDEX introduced the first non-addictive "Zero-toluene" PVC Pipe Cement in the Philippines

Since does not contain the banned solvent, Toluene, no PDEA permits are needed for storing, selling and using. Hassle-free.

This is also the first and only PVC pipe cement to cure in 15 minutes and resist up to 232 psi working pressure with MOLDEX Blue PVC-U pipes and fittings. Plumbers no longer need to wait for 24 hours for their new connections to fully cure. Talk about labor and time savings.

MOLDEX is the no. 1 premium pipe manufacturer in the Philippines. The story of our firsts is a long list of pioneering product innovation that improves people's lives.

MOLDEX introduced the first electrical PVC-U moulding with patented double-lock profile technology in the Philippines

Whatever it is, the way you tell your story online can make all the difference.

MOLDEX was the first to introduce the metal-reinforced pure EPDM/NBR integrated seals for PVC-U Mains

Its embedded stiffener, multi-coated carbon steel ring/band is not exposed to water pressure and oxidation. This product is widely used by major water concessionaires and water districts nationwide to minimize non-revenue water.